Water damage in residential and commercial buildings represents one of the most costly and structurally threatening issues property owners face today. The implementation of proper waterproofing systems in wet areas, particularly bathrooms and sanitary facilities, serves as the primary defense against moisture infiltration that can compromise building integrity, promote harmful microbial growth, and necessitate expensive remediation procedures. Contemporary waterproofing technologies have evolved significantly from traditional approaches, incorporating advanced polymer sciences and innovative application methodologies that deliver superior performance characteristics and extended service life.

The fundamental principle underlying effective waterproofing involves creating a continuous barrier system that prevents liquid water penetration while managing vapor transmission in accordance with building physics requirements. Modern waterproofing systems must address multiple challenge factors including structural movement, temperature fluctuations, hydrostatic pressure variations, and chemical exposure from cleaning agents and personal care products. Understanding these complex interactions is essential for specifying appropriate materials and installation procedures that ensure long-term performance reliability.

Understanding Waterproofing System Architecture

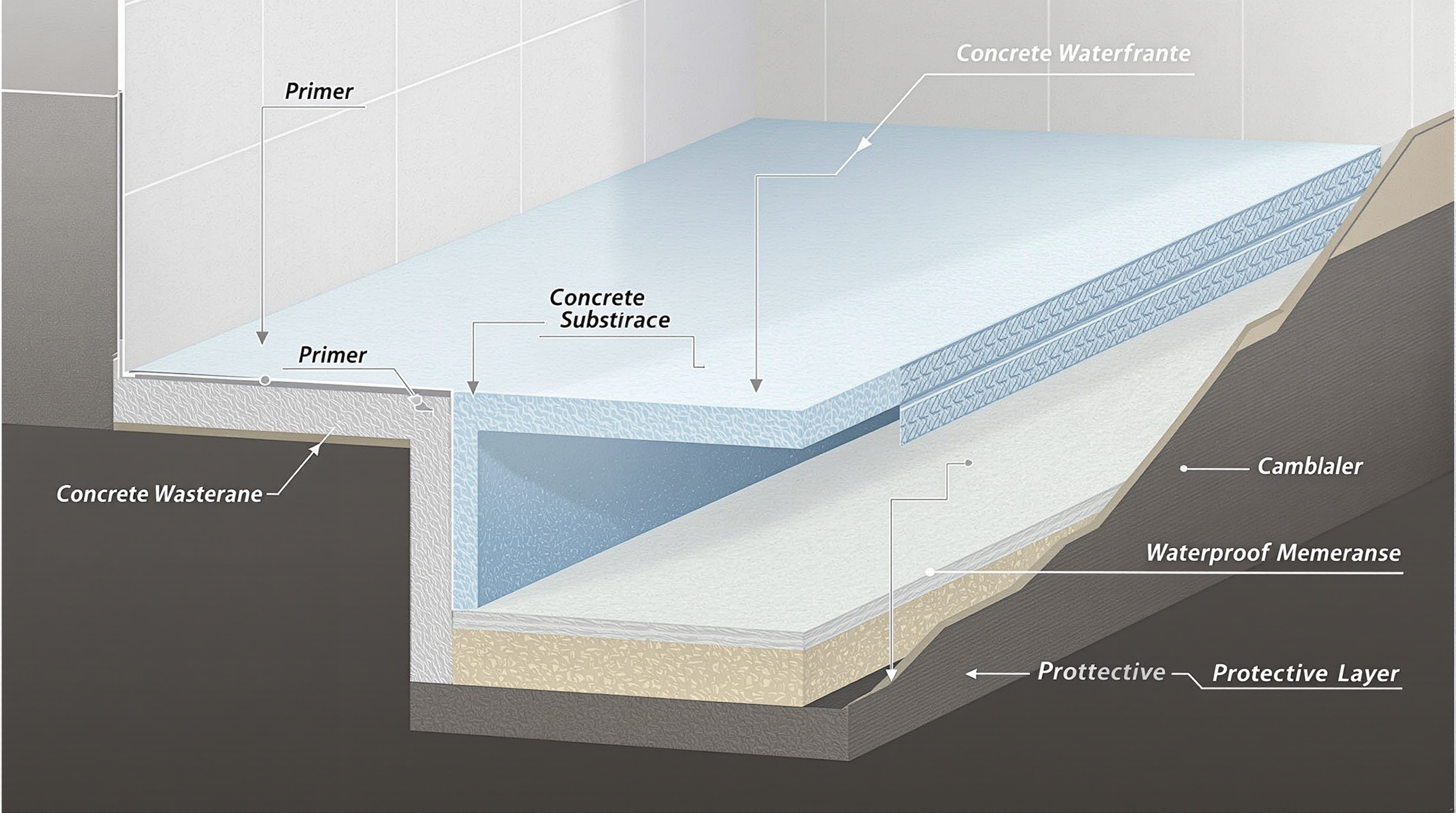

Contemporary waterproofing systems operate on multilayer architectural principles that distribute protective functions across specialized component layers. The primary waterproof membrane forms the core barrier element, while supporting layers provide substrate preparation, adhesion enhancement, mechanical protection, and finish compatibility functions. This systematic approach eliminates single points of failure that characterized earlier waterproofing methodologies and provides redundant protection mechanisms.

The substrate preparation layer establishes the foundation for waterproofing system performance through surface consolidation, void filling, and profile correction procedures. Modern substrate treatment technologies utilize penetrating consolidants that chemically react with cement matrices to enhance surface stability and reduce porosity. These preparatory treatments significantly improve membrane adhesion performance and minimize the risk of substrate-related failure modes such as delamination or cracking transmission.

Primer systems represent a critical interface component that optimizes adhesion between prepared substrates and waterproof membranes. Contemporary primer formulations incorporate coupling agents that form molecular bridges between dissimilar materials, ensuring cohesive bonding under diverse environmental conditions. The selection of appropriate primer chemistry depends on substrate composition, membrane type, and service environment characteristics, with specialized formulations available for challenging applications such as green concrete or contaminated surfaces.

Advanced Membrane Technologies and Performance Characteristics

Modern waterproof membrane technologies encompass several distinct material families, each offering specific advantages for particular application requirements. Liquid-applied membranes utilize reactive polymer chemistries that cure in place to form seamless barrier systems conforming precisely to complex geometric configurations. These systems excel in applications requiring detailed waterproofing around penetrations, corners, and irregular surfaces where prefabricated membrane installation would be challenging or compromised.

Elastomeric membrane compounds based on polyurethane, acrylic, and hybrid polymer technologies provide exceptional flexibility and crack-bridging capabilities essential for accommodating structural movement without integrity loss. Advanced formulations incorporate plasticizers and stabilizers that maintain elasticity throughout extended service periods while resisting degradation from ultraviolet exposure, ozone attack, and chemical contact. The superior elongation characteristics of modern elastomeric membranes enable them to accommodate substrate movements exceeding traditional material limitations.

Self-adhering sheet membrane systems represent significant technological advancement in prefabricated waterproofing solutions. These products eliminate the need for adhesive application during installation while providing immediate bond development upon contact with prepared surfaces. Contemporary self-adhering membranes utilize pressure-sensitive adhesive technologies that develop full bond strength over time while maintaining repositioning capability during initial placement. This characteristic substantially reduces installation complexity and minimizes weather-related application constraints.

| Membrane Type | Service Temperature Range | Elongation Capacity | Application Method | Typical Thickness |

| Liquid Polyurethane | -40°F to 180°F | 300-500% | Spray/Brush/Roll | 40-60 mils |

| Modified Bitumen Sheet | -20°F to 160°F | 50-100% | Heat Welded/Adhered | 90-180 mils |

| EPDM Rubber Sheet | -45°F to 300°F | 400-600% | Mechanically Fastened/Adhered | 45-90 mils |

| TPO Thermoplastic | -40°F to 180°F | 300-400% | Heat Welded | 45-100 mils |

Hybrid membrane technologies combine benefits from multiple material systems to address specific performance requirements that single-component systems cannot adequately satisfy. These advanced formulations might incorporate reinforcing fabrics for enhanced tensile strength, ceramic additives for improved abrasion resistance, or antimicrobial agents for enhanced hygiene performance. The development of hybrid systems reflects the increasing sophistication of waterproofing applications and the demand for customized performance characteristics.

Critical Installation Procedures and Quality Control Methods

Professional waterproofing installation requires adherence to precise procedural sequences that ensure optimal system performance and longevity. Surface preparation protocols establish the foundation for successful installation through comprehensive cleaning, repair, and conditioning procedures. Contemporary preparation methods utilize mechanical and chemical techniques to achieve specified surface profiles and cleanliness standards that promote maximum adhesion development.

Temperature and humidity monitoring throughout the installation process represents a critical quality control element that significantly influences membrane curing behavior and final performance characteristics. Modern waterproofing materials incorporate temperature-sensitive catalysts and moisture-dependent curing mechanisms that require specific environmental conditions for optimal development. Professional installers utilize environmental monitoring equipment to verify suitable conditions and adjust application procedures accordingly.

Seam integrity verification procedures ensure continuity of the waterproof barrier at membrane joints and terminations where failure risks are typically highest. Advanced testing methods including electronic leak detection, pressure testing, and infrared thermography enable comprehensive quality verification without destructive investigation. These non-destructive testing approaches provide immediate feedback on installation quality and enable corrective actions before system completion.

Application thickness control ensures adequate material coverage while avoiding waste and performance degradation associated with excessive application. Wet film thickness gauges and electronic measuring devices enable real-time monitoring of application rates and uniform coverage achievement. Proper thickness control becomes particularly critical with liquid-applied systems where insufficient coverage can create weak points while excessive application may cause adhesion problems or extended curing periods.

Integration with Modern Building Systems and Sustainable Practices

Contemporary waterproofing design must consider integration requirements with modern building systems including radiant heating, advanced drainage networks, and building automation technologies. The interaction between waterproof membranes and these systems requires careful specification to ensure compatibility and prevent performance conflicts. For example, radiant heating systems generate elevated temperatures that may exceed standard membrane temperature ratings, necessitating specialized high-temperature formulations.

Sustainable waterproofing practices increasingly emphasize material selection criteria including recycled content, low volatile organic compound emissions, and end-of-life recyclability potential. Green building certification programs such as LEED recognize waterproofing contributions to building performance through moisture control, indoor air quality maintenance, and durability enhancement. The specification of environmentally responsible waterproofing systems supports broader sustainability objectives while maintaining essential protective performance.

Building information modeling integration enables three-dimensional waterproofing system design and coordination with other building components during the planning phase. This technological approach reduces field conflicts, optimizes material usage, and facilitates quality control through detailed installation sequencing and specification development. Advanced modeling capabilities support performance analysis and life-cycle cost evaluation that inform material selection and system design decisions.

| System Component | Function | Material Options | Performance Criteria |

| Substrate Preparation | Surface stabilization and profile correction | Epoxy primers, acrylic sealers, cementitious levelers | Tensile adhesion > 200 psi |

| Primary Membrane | Water barrier and crack bridging | Polyurethane, modified bitumen, EPDM | Elongation > 300%, tear resistance > 200 lbf/in |

| Protection Layer | Mechanical damage prevention | Geotextile fabric, rigid boards, protective coatings | Puncture resistance, compressive strength |

| Finish System | Aesthetic and functional surface | Ceramic tile, natural stone, decorative coatings | Adhesion compatibility, thermal movement |

The specification of waterproofing systems within the context of whole-building moisture management requires understanding of vapor drive mechanisms and seasonal variation patterns. Effective moisture management prevents condensation accumulation within building assemblies that could compromise structural integrity or indoor environmental quality. Modern building science principles guide the selection of vapor permeable or impermeable membrane systems based on climate conditions and building construction characteristics, as referenced in building physics literature such as moisture control in buildings.

Performance Monitoring and Maintenance Strategies

Long-term waterproofing system performance depends on implementing appropriate monitoring and maintenance protocols that identify potential issues before they develop into costly failure conditions. Preventive maintenance programs include regular inspection procedures, minor repair protocols, and performance testing schedules that maintain system integrity throughout the intended service life. Professional maintenance approaches utilize specialized diagnostic equipment to assess membrane condition and identify areas requiring attention.

Electronic monitoring systems provide continuous assessment of waterproofing performance through embedded sensors that detect moisture intrusion or membrane damage. These advanced systems enable immediate response to developing problems and provide valuable performance data for system optimization and life-cycle analysis. The integration of monitoring technology with building management systems creates automated alert capabilities and historical performance tracking.

Repair and restoration procedures for aging waterproofing systems increasingly utilize compatible materials and techniques that extend service life without requiring complete system replacement. Modern repair technologies include injection systems for crack sealing, overlay membranes for surface restoration, and localized replacement methods for damaged areas. These approaches provide cost-effective alternatives to complete system replacement while maintaining protective performance standards.

The economic analysis of waterproofing investments demonstrates substantial long-term value through prevented damage costs, reduced maintenance requirements, and enhanced building durability. Professional cost-benefit analysis considers initial installation costs, expected service life, maintenance requirements, and potential failure consequences to determine optimal system specifications. This analytical approach supports informed decision-making that balances performance requirements with budget constraints while ensuring adequate protection against water damage risks.

Contemporary waterproofing technologies provide building owners and construction professionals with sophisticated tools for creating durable, reliable moisture protection systems that meet the demanding requirements of modern construction. The successful implementation of these advanced systems requires comprehensive understanding of material properties, installation procedures, and performance monitoring techniques that ensure optimal results throughout the intended service life. Through careful specification, professional installation, and proactive maintenance, modern waterproofing systems deliver exceptional value and protection against the costly consequences of water intrusion in building environments.

73valve.com

73valve.com